SUPER-Series NA Type

- TOP

- products Info

- SUPER-Series NA Type

SUPER-Series NA TypeNA Type

An independent motor is mounted for each shaft, enabling the independent operation on each shaft.

The nut tapping mechanism itself is a dedicated machine for the bent shank nut tap similar to N series,

and either old hard type or touch panel.

The screw cutting failure detection mechanism using sequencer control is mounted as the standard. As for the machine with a touch panel, the mechanism to indicate the torque status (motor current value) on the screen during processing is added.

It is possible to numerically set the number of revolution per stroke as the number of screw threads on either the digital panel meter or touch panel.

By changing setting on the built-in timer, the mechanical motion environment that matches the work characteristics can be established.

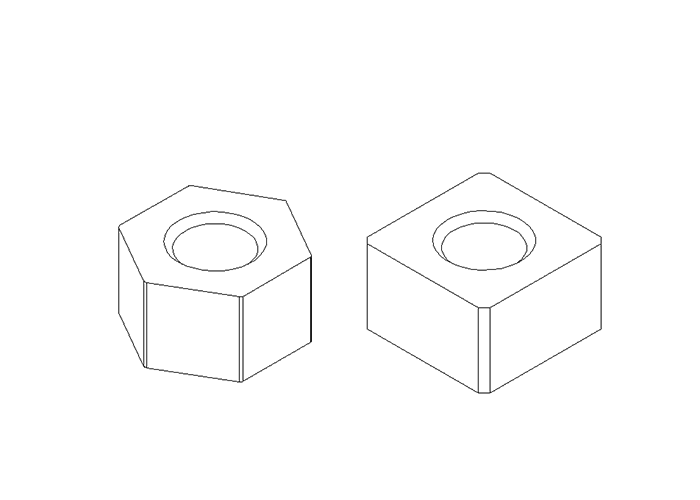

Select by shape of nut

Hex/Square nut

SUPER-NA Type

| Range of screw processing | |

|---|---|

| SUPER-2NA | Hex nut

M4~M6 |

| Square nut

M4~M6 |

|

| SUPER-3NA | Hex nut

M6~M12 |

| Square nut

M6~M10 |

|

| SUPER-5NA | Hex nut

M10~M20 |

| Square nut

M10~M18 |

|

| SUPER-7NA | Hex nut

M20~M24 |

| Square nut

M20~M24 |

|

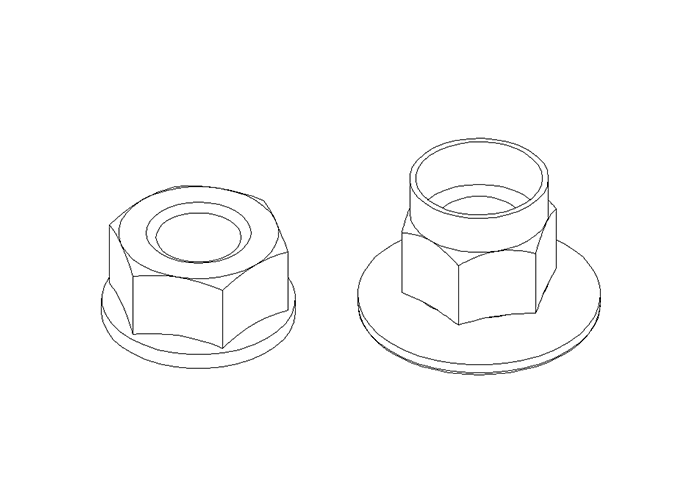

Flange nut

SUPER-NFA Type

| Range of screw processing | |

|---|---|

| SUPER-2NFA | M3~M5 |

| SUPER-3NFA | M5~M10 |

| SUPER-5NFA | M10~M16 |

| SUPER-7NFA | M18~M24 |

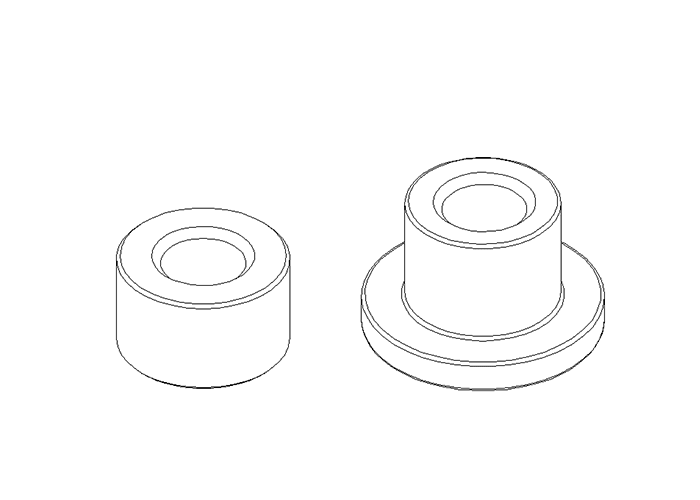

Round nut

SUPER-NRA Type

| Range of screw processing | |

|---|---|

| SUPER-2NRA | M2.5~M5 |

| SUPER-3NRA | M6~M10 |

| SUPER-5NRA | M10~M16 |

| SUPER-7NRA | M18~M22 |

SUPER-Series NA Type

NA Type

| Model | SUPER-2NA | SUPER-3NA | SUPER-5NA | SUPER-7NA |

|---|---|---|---|---|

| Range of screw processing | Hex nut

M4~M6 |

Hex nut

M6~M12 |

Hex nut

M10~M20 |

Hex nut

M20~M24 |

| Square nut

M4~M6 |

Square nut

M6~M10 |

Square nut

M10~M18 |

Square nut

M20~M24 |

|

| Nut tapping style | Biaxial slide air system Spring pushing type | |||

| Work fixing method | Turn stop type hexagonal guide | |||

| Shape of tap used

(Bent tap) |

L180mm×25R | L245mm×30R | L375mm×45R | L520mm×65R |

| Tap replacement style | Quick replacing type (Bent guide door close / open) | |||

| Work feeding style | Hopper | |||

| Stroke setting for main shaft rotation & screw thread cutting | Preset type (the number of threads setting) Digital panel meter or touch panel | |||

|

Main shaft motor spec.

(Induction motor x2) |

0.4KW (3 phase/4P) | 1.5KW (3 phase/4P) | 2.2KW (3 phase/4P) | 3.7KW (3 phase/4P) |

| Main shaft rotation range | 360~3600rpm | 950~2500rpm | 600~1500rpm | 400~1000rpm |

| Main shaft control method | Inverter | |||

|

Coolant pump

(Dip type coolant pump) |

180W (3 phase/2P) | 400W (3 phase/2P) | ||

|

Hopper driving motor

(Gear motor) |

100W (3 phase/4P) | 400W (3 phase/4P) | ||

|

Chip separator

(Induction motor) |

25W (3 phase/4P) | |||

| Hydraulic unit | * | |||

| Control device | Sequencer / digital panel meter / various lamp switches | |||

| Production counter | Digital panel meter (Tap lifetime / total count) | |||

| Failure detection items | Chamfer failure / clogging / empty / doubling / reamer torque | |||

| Other remarks | In case of a touch panel mounted machine, various types of switches and display devices (alarm, motion monitor, etc.) are concentrated on the screen. | |||

| Main replacing parts | Chute / guide / mouthpiece / bent guide back panel Chute / guide / mouthpiece / bent guide back panel | |||

| Cutting lubricant tank capacity | 60L | 120L | 200L | |

| Machine size | 840mm×1200mm

×H1430mm |

910mm×1220mm

×H1530mm |

1060mm×1680mm

×H1550mm |

1120mm×1900mm

×H1560mm |

| Machine weight | 450kgs | 500kgs | 1000kgs | 1450kgs |

| Other standard functions | Auto recovery function (when empty / clogging happened) | |||

| Options / others | Defective product ejection function | |||

| Production volume per minute (for reference) | * | |||

SUPER-Series NA Type

NFA Type

| Model | SUPER-2NFA | SUPER-3NFA | SUPER-5NFA | SUPER-7NFA |

|---|---|---|---|---|

| Range of screw processing | M3~M5 | M5~M10 | M10~M16 | M18~M24 |

| Nut tapping style | Biaxial slide air system Spring pushing type | |||

| Work fixing method | Flange guide (Turn stopper by chip) | |||

| Shape of tap used

(Bent tap) |

L180mm×25R | L245mm×30R | L385mm×45R | L530mm×65R |

| Tap replacement style | Quick replacing type (Bent guide door close / open) | |||

| Work feeding style | Hopper or Parts feeder | |||

| Stroke setting for main shaft rotation & screw thread cutting | Preset type (the number of threads setting) Digital panel meter or touch panel | |||

|

Main shaft motor spec.

(Induction motor x2) |

0.4KW (3 phase/4P) | 1.5KW (3 phase/4P) | 2.2KW (3 phase/4P) | 3.7KW (3 phase/4P) |

| Main shaft rotation range | 360~3600rpm | 950~2500rpm | 600~1500rpm | 400~1000rpm |

| Main shaft control method | Inverter | |||

|

Coolant pump

(Dip type coolant pump) |

180W (3 phase/2P) | 400W (3 phase/2P) | ||

|

Hopper driving motor

(Gear motor) |

100W (3 phase/4P) | 400W (3 phase/4P) | ||

|

Chip separator

(Induction motor) |

25W (3 phase/4P) | |||

| Hydraulic unit | * | |||

| Control device | Sequencer / digital panel meter / various lamp switches | |||

| Production counter | Digital panel meter (Tap lifetime / total count) | |||

| Failure detection items | Chamfer failure / clogging / empty / doubling / reamer torque | |||

| Other remarks | In case of a touch panel mounted machine,rious types of switches and display devices (alarm, motion monitor, etc.) are concentrated on the screen. | |||

| Main replacing parts | Chute / hydraulic chuck / chuck fixing board / mouthpiece / bent guide back panel | |||

| Cutting lubricant tank capacity | 60L | 120L | 200L | |

| Machine size | 840mm×1200mm

×H1430mm |

910mm×1220mm

×H1530mm |

1060mm×1680mm

×H1550mm |

1120mm×1900mm

×H1560mm |

| Machine weight | 450kgs | 500kgs | 1200kgs | 1500kgs |

| Other standard functions | Auto recovery function (when empty / clogging happened) | |||

| Options / others | Defective product ejection function | |||

| Production volume per minute (for reference) | * | |||

SUPER-Series NA Type

NRA Type

| Model | SUPER-2NRA | SUPER-3NRA | SUPER-5NRA | SUPER-7NRA |

|---|---|---|---|---|

| Range of screw processing | M2.5~M5 | M6~M10 | M10~M16 | M18~M22 |

| Nut tapping style | Biaxial slide air system Spring pushing type | |||

| Work fixing method | Hydraulic chuck guide | |||

| Shape of tap used

(Bent tap) |

L180mm×25R | L245mm×30R | L385mm×45R | L530mm×65R |

| Tap replacement style | Quick replacing type (Bent guide door close / open) | |||

| Work feeding style | Hopper or Parts feeder | |||

| Stroke setting for main shaft rotation & screw thread cutting | Preset type (the number of threads setting) Digital panel meter or touch panel | |||

|

Main shaft motor spec.

(Induction motor x2) |

0.4KW (3 phase/4P) | 1.5KW (3 phase/4P) | 2.2KW (3 phase/4P) | 3.7KW (3 phase/4P) |

| Main shaft rotation range | 360~3600rpm | 950~2500rpm | 600~1500rpm | 400~1000rpm |

| Main shaft control method | Inverter | |||

|

Coolant pump

(Dip type coolant pump) |

180W (3 phase/2P) | 400W (3 phase/2P) | ||

|

Hopper driving motor

(Gear motor) |

100W (3 phase/4P) | 400W (3 phase/4P) | ||

|

Chip separator

(Induction motor) |

25W (3 phase/4P) | |||

| Hydraulic unit | 0.75 KW (3 phase/4P)

Max. using pressure 3.5MPa |

1.5 KW (3 phase/4P)

Max. using pressure 3.5MPa |

||

| Control device | Sequencer / digital panel meter / various lamp switches | |||

| Production counter | Digital panel meter (Tap lifetime / total count) | |||

| Failure detection items | Chamfer failure / clogging / empty / doubling / reamer torque | |||

| Other remarks | In case of a touch panel mounted machine,rious types of switches and display devices (alarm, motion monitor, etc.) are concentrated on the screen. | |||

| Main replacing parts | Chute / hydraulic chuck / chuck fixing board / mouthpiece / bent guide back panel | |||

| Cutting lubricant tank capacity | 60L | 120L | 200L | |

| Machine size | 900mm×1200mm

×H1430mm |

1050mm×1220mm

×H1530mm |

1160mm×1660mm

×H1580mm |

1220mm×1900mm

×H1560mm |

| Machine weight | 480kgs | 600kgs | 1250kgs | 1550kgs |

| Other standard functions | * | |||

| Options / others | Defective product ejection function | |||

| Production volume per minute (for reference) | * | |||

Please do not hesitate to contact us

if you have any questions about products.

-

HeadTel.03-3743-5321 / Fax.03-3744-5253

20-16 Higashi-kojiya 1-chome,

Ota City, Tokyo 144-0033 Japan